Making maple syrup is a labor of love!

We are open any day, from the beginning of March until Mid-April, you see steam rising out of the roof.

Tim begins tapping maple trees in late winter/early spring. He carefully chooses the spot to tap to avoid harming the tree. A small, shallow hole is drilled into the sapwood of the maple tree, about 5 1/6’ in diameter and about 1.5 to 2” deep.

Then we tap the spile in lightly with a hammer, which is how the sap flows out of the tree for Tim to gather.

When the temperatures at night are in the 20-degree Fahrenheit range and the temperature climbs about 40 degrees Fahrenheit during the day, the sap begins to rise in the tree and flows into our network of sap lines, as well as some that drip the sap into the traditional collection method, buckets.

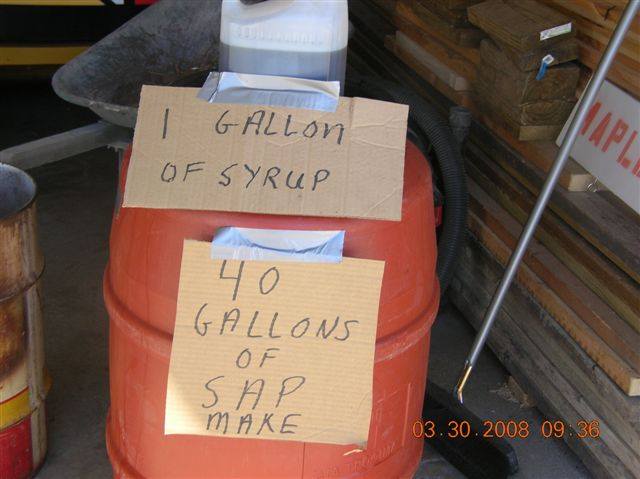

Maple sap is only 2% sugar and really looks just and tastes like slightly sweet water! It takes about 40 gallons of sap (depending on the sugar content) to produce a single gallon of syrup.

The sap is collected in a large road-side tanks and the maple syrup magic begins.

Tim gathers the sap and brings it to our sugar house to be processed and evaporated into maple syrup.

Once the sap reaches Turkey Street Maples sugar house, it is pumped into our stainless-steel sap tanks and filtered.

Once it is ready for the evaporator, the sap is boiled on our wood-fired evaporator and the water in the sap is evaporated until the sap has reached the proper temperature (7 degrees Fahrenheit above the boiling point of water) and density which is the consistency of 66.9 percent sugar.

Tim also grades our syrup based on color and tasted using the universal grading system. This system is used throughout the 13 maple producing states in the US and Canada, so that all syrup is graded consistently.

Finally, Turkey Street Maples’ delicious, sweet 100% pure New Hampshire maple syrup is bottled into custom jugs for our customers.

The Science and Artistry of Maple Sugaring

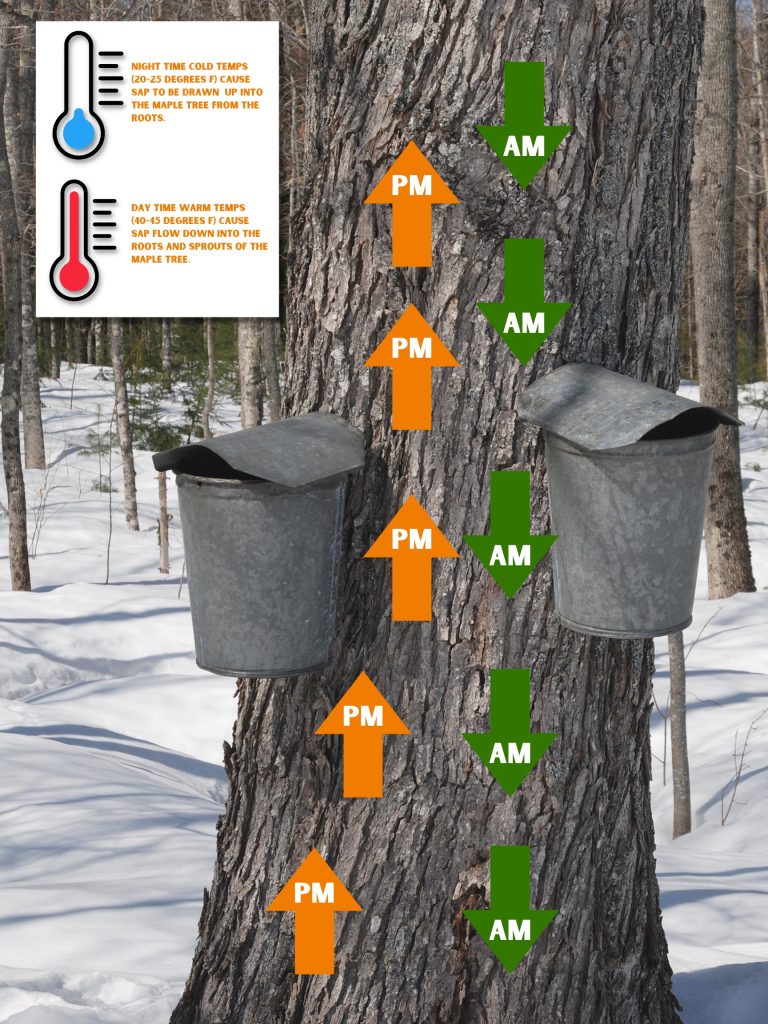

When the temperature falls to 20-25 degrees F the pressure inside the tree may become negative in relation to atmospheric pressure.

As the maple tree begins to freeze, the sap is drawn up into the tree through the sapwood, which acts as a series of straws, that connect with the tree’s roots.

During the day the rises above 40 degrees F pressure is created inside the tree that pushes the sap back down through the sapwood to the bottom and through its sprouts and roots. During this process, there is an excess of sap and that is what sugar makers gather to boil into delicious maple syrup.

This sap flow continues while the cycle of warm and below-freezing temperatures repeats until the nights are no longer freezing.

Sugar makers generally look for other signs as a signal that the season is coming to an end.

One indication is that the sap may become discolored and have a bitter taste. Another is when the buds on the trees become the size of a mouse’s ear.